Hyundai Global Service (HGS), the aftercare division of shipbuilder and engine maker Hyundai Heavy Industries and the global technology company ABB Turbocharging have signed an agreement to offer an engine part-load optimisation (EPLO) service in line with the International Maritime Organization’s (IMO) requirements, for shipowners seeking to cut emissions.

Ahead of the entry into force of the Energy Efficiency Existing Ship Index (EEXI) and Carbon Intensity Index (CII) regulations in 2023, many vessel owners are looking to engine power limitation as a solution.

“Optimising engines for part-load operation is a reliable and economically feasible solution to minimise environmental impact and improve the operational efficiency of vessels,” stated HGS.

The EPLO service can help shipowners find the optimum power range for their engine power limitation, optimise combustion within the reduced load range and reduce fuel consumption, emissions and maintenance costs.

In particular, HGS and ABB that can fully manage the project autonomously will provide a full, turnkey package covering engines, turbocharger retrofit solution and nitrogen oxides (NOx) certification, supported by digital solutions, to monitor the in-service performance of engines and turbochargers.

The service also enables shipowners to optimise operations on an ongoing basis with the inclusion of the engine diagnosis solution ABB Ability Tekomar XPERT, which offers personalised advisory based on real-time, in-service data that helps shipowners to further reduce fuel costs and CO2 emissions, according to a statement.

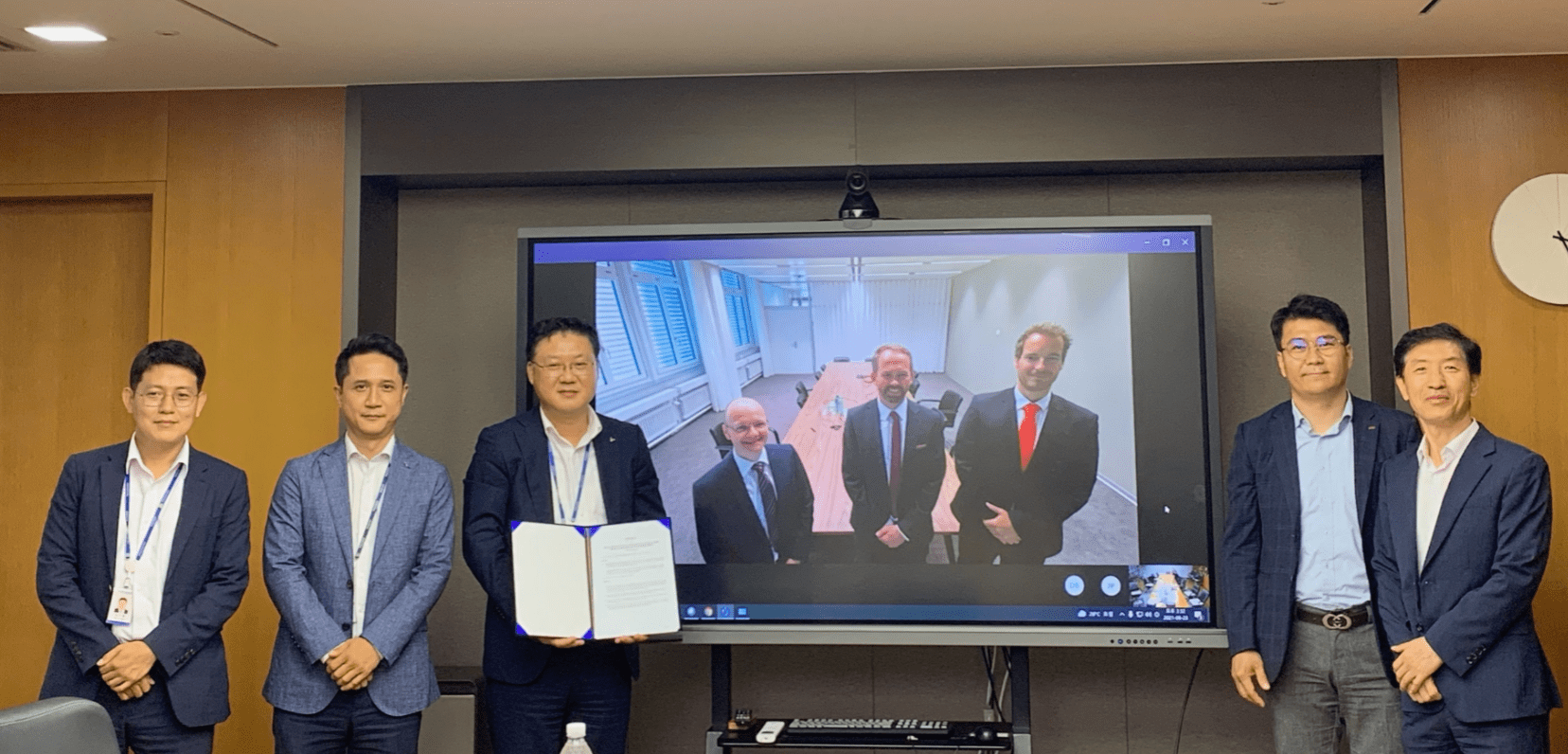

The officials of the two companies expressed the benefits that will arise from their partnership.

“This strategic technical alliance in response to IMO’s new regulations will offer excellent value to our shipowner customers as they aim to reduce emissions and improve efficiency,” said Sung Ki Ahn, HGS Managing Director of Green Engineering Sales.

In addition, Dirk Balthasar, ABB Turbocharging Head of Global Service Sales, noted, “With HGS’ engine technical service capabilities and experience of project management, and ABB’s turbocharging know-how, upgrade capabilities and unique software solutions, this partnership offers a holistic solution that will be hard to find elsewhere.”

The companies can offer several forms of optimisation, targeting specific customer needs and vessel operating profiles. This ranges from installing wastegates to engine derating or turbocharger cut-out, according to a statement.