As global trade continues to increase, ports face increasing pressure to increase efficiency, reduce operating costs and adapt to volatile volumes of cargo. Traditional infrastructure development lags behind demand, leading to congestion, delay and rising storage fees. Overseas shipping volatility and worldwide disruptions such as pandemics and supply chain catastrophes also make long-term planning by port authorities challenging. In response to such issues, ports worldwide have turned to rapid-deploy fabric structures as a cost-effective and flexible alternative. The structures provide a timely solution to volatile logistics demands without needing enormous, time-consuming building schemes.

What Are Rapid-Deploy Fabric Structures?

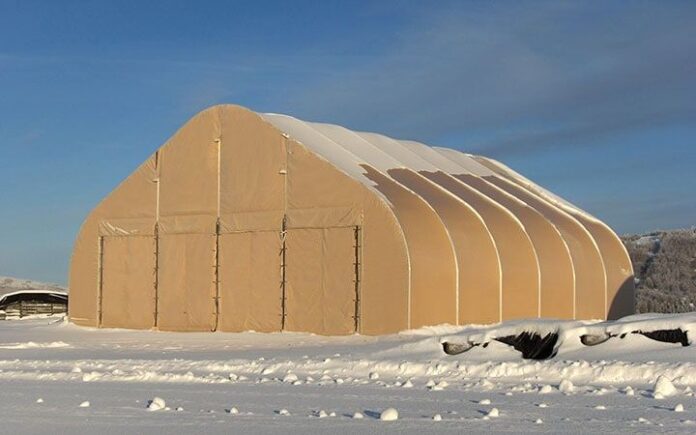

Rapid-deploy fabric structures have steel or aluminum frames supporting high-strength fabric. Unlike conventional warehouses and storage centers, they can be built in days instead of years to provide immediate relief to ports with space constraints. The lightweight but very durable structure of such buildings provides an ideal solution to temporary and permanent applications alike.

The materials used in such buildings can withstand harsh weather conditions such as heavy rains, high-speed wind and extreme temperatures and therefore can be utilized in ports found in diverse geographies. The modular design of such buildings can be readily expanded, reconfigured or relocated as needed, offering a level of operational versatility that traditional buildings do not have.

The Role of Pre-Engineered Fabric Buildings in Port Logistics

An important evolution in this sector is pre-engineered fabric building that makes it even more convenient to deploy. The buildings are designed and constructed off-site to permit accurate engineering and more rapid assembly at the port. Port operators can enhance efficiency in managing cargo, create more space to store it and boost overall operating responsiveness by including a pre-engineered fabric building in their logistics strategy.

Pre-engineered structures also have several other advantages such as being able to accommodate complex climate control systems, structurally reinforced designs and customized entrance and exit points to allow optimal workflow. Many port facilities that handle perishable products, high-value cargo or time-sensitive shipments benefit from using pre-engineered fabric buildings to create regulated environments. The ability to store products at optimal conditions without increasing expenses is why pre-engineered fabric buildings become a viable option for ports of all sizes.

Speed and Efficiency in Deployment

Among the greatest advantages of rapid-deploy fabric structures is their rapid installation. Unlike traditional structures that take years or months to construct, fabric structures can be deployed in days or weeks. Rapid deployment assures that ports can respond to sudden volume increases in cargo, seasonal demand or immediate storage requirements without compromising efficiency in operations.

This speed is particularly valuable in periods of crisis. For instance, in cases of natural disasters or sudden supply chain disruptions, ports must be able to deploy functional storage and operating hubs at speed. Whether it’s temporary housing of displaced containers, freeing up space to take in emergency shipments or facilitating humanitarian aid operations, being able to deploy infrastructure at speed is a game-changer.

Cost Savings and Economic Benefits

Ports have limited budgets and minimizing capital expenses is a primary concern. The rapid-deployment fabric structures have a considerable cost benefit over conventional infrastructure. The prefabricated modules reduce labor and material expenses and their modularity allows expansion or movement with minimal effort. Lower maintenance and energy efficiency also means long-term cost benefits to port authorities and terminal operators.

Besides direct labor and construction cost savings, such facilities also lead to lower downtime. The more quickly a port can integrate more storage or operating space, the more quickly it can move more traffic in terms of cargo, avoiding bottlenecks and lost business. Beyond that, ports can make their land-use planning more effective by utilizing such facilities in low-occupancy areas, essentially turning idle space into efficient logistics hubs.

Versatility to Meet Various Port Applications

Rapid-deployment fabric structures do not necessarily have to be limited to general storage of cargo. Due to their versatility, they can be utilized to serve multiple purposes in a port environment. From bulk commodity storage and refrigerated products to covered working space for maintenance staff, such structures can be configured to meet a variety of operations. Some ports also utilize them as temporary customs inspection stations, quarantine areas and container transloading stations.

Another recent application is their role as temporary administrative centers or offices. If ports expand their operations or have long-term building projects implemented, flexible office space can assist in ensuring that key staff can be located close to significant logistics operations without disrupting workflow. The fact that they can be utilized to fit a range of applications also highlights their role as a central part of port management today.

Environmental and Sustainability Benefits

Environmental concern is a priority in the shipping and logistics industry. Rapid-deployment fabric structures contribute to green initiatives by reducing carbon footprints associated with traditional buildings. Most of such structures incorporate recyclable materials, natural daylighting and energy-efficient insulation and thus become a green solution to help port authorities meet environmental regulations and corporate sustainability programs.

Ports that aim to minimize their ecological footprint can also integrate renewable energy solutions into their fabric buildings. Solar panels, windmills and rainwater harvesting systems can be integrated into their buildings to make them more sustainable and reduce their energy expenses overall. The fact that green infrastructure can be implemented without overloading their resources with heavy expenses makes such buildings a viable alternative for forward-thinking port operators.