The port equipment manufacturing company Kalmar has received a repeat order of six Automatic Stacking Cranes (ASC) from Victoria International Container Terminal (VICT).

The order was booked in the third quarter of 2021 order intake of Cargotec, the mother company of Kalmar, with an expected delivery time during the second quarter of 2023.

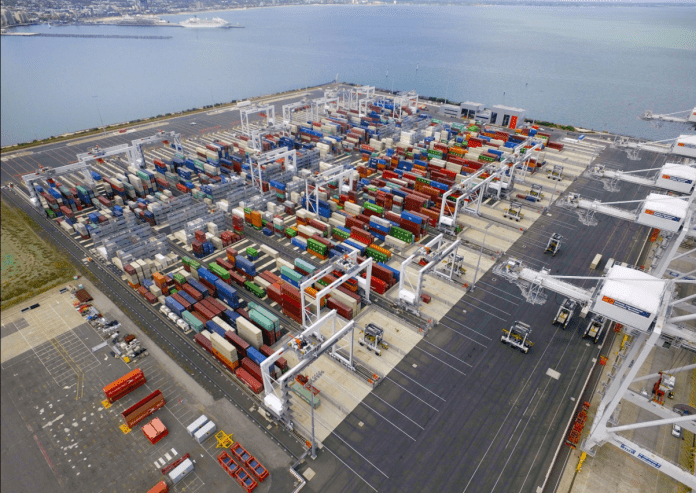

Established in 2017, the International Container Terminal Services, Inc (ICTSI) owned VICT is Australia’s first fully automated container terminal with an operating capacity of over 1 million TEU and an extent of 350,000m², located in the Port of Melbourne.

The six new cranes which are part of VICT’s capacity expansion program will join the current fleet of 20 Kalmar ASC of the terminal, that have been delivering truck turn times of sub-35 minutes.

Kalmar will also be responsible for the maintenance and support of the automated container handling software solution operating at VICT as well as related technical support, with the sign of a three-year Kalmar Parts Care agreement in 2020.

“The cranes will be delivered fully erected and tested to ensure rapid, smooth integration into the terminal’s automated operations,” said the Finish manufacturing company.

VICT’s automated operations are powered by Kalmar One Automation System, a complete end-to-end system that combines Kalmar automated equipment and a pre-integrated and tested software solution.

Earlier this year, ICTSI’s terminal ordered six Kalmar AutoShuttles that will be delivered by the end of this year, increasing their total fleet to 17 units.

Jon Wheeler, Chief Operating Officer of VICT noted the advantages that the machines will bring into the terminal, pointing out that “the yard capacity expansion and the new Automatic Stacking Cranes will allow us to increase the productivity of our operations to meet the growing customer demand on both quay and landside.”

“The additional storage blocks will also add resiliency, allowing for improved planned maintenance, minimising disruption to our stakeholders,” he said.