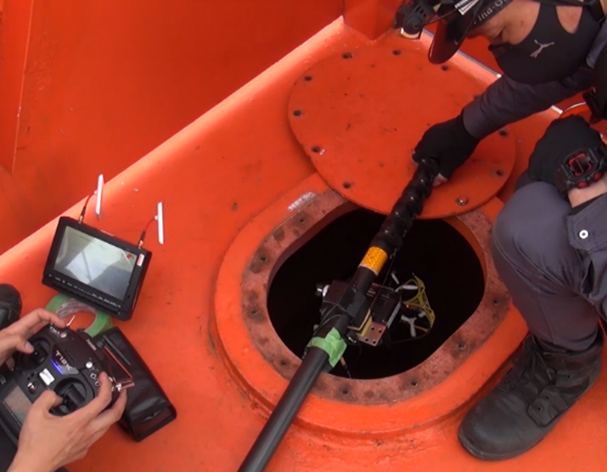

MITSUI E&S and Liberaware, a developer of small non-GPS drones, conducted a demonstration experiment by inspecting the interior structure of the quayside container crane using the small industrial drone “IBIS” which was particularly developed for indoor spaces.

In order to improve the safety and quality of container crane internal structure inspection, instead of using the traditional inspection method that requires inspection workers to enter the structure, Liberaware’s small drone IBIS was used in this demonstration experiment to take a video of the crane’s internal structure, which was then evaluated in an office.

It has been proved that inspection applying this new technology may increase the safety of inspection employees, improve inspection quality through video recording, and minimise the length of after-inspection-investigation required before repair work.

In the future, MITSUI E&S may provide a service for inspections of the interior structures of container cranes using IBIS in response to client demands for thorough periodic examination of container cranes. MITSUI E&S is also exploring linking the inspection data with the Next Generation Crane Monitoring System (CARMS) created by MITSUI E&S to improve crane maintenance and management efficiency.