The slightest deviation in the machining, polishing, and finishing of ships’ propeller blades could result in underwater radiated noise and cavitation, even if defects are within the maximum tolerance allowed by classification societies and the ISO 484-1 standard, according to a new research.

A Canada Transport-funded study on the impact of manufacturing tolerances on propeller performance – carried out by the Memorial University of Newfoundland, DRDC Atlantic Research Centre, and propeller manufacturer Dominis Engineering – found the slightest change in propeller geometry resulted in “significant” cavitation, and much earlier than previously thought.

ISO 484-1:2015 has been a propeller standard since 1982, and despite revisions in 2015 and 2022, the permissible tolerance and geometry remain unaltered.

“The 0.5mm defect tested is one of the tightest ISO 484-1 propeller manufacturing tolerances yet it has been demonstrated that it affects cavitation inception significantly and detrimentally. The rules need tightening up,” stated Bodo Gospodnetic, project lead and Dominis Engineering president.

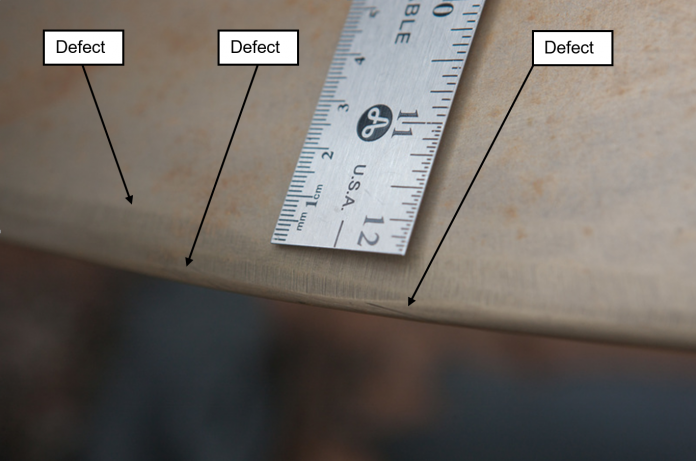

In a three-year experiment that finished last year, the behaviour of a segment of a propeller blade with leading edge defects of 94m, 250m, and 500m was examined using Computational Fluid Dynamics (CFD) at the DRDC-Atlantic Research Centre and the Memorial University of Newfoundland.

“Experimental results show that current widely accepted propeller manufacturing tolerances as stated in the ISO standard need to be thoroughly evaluated and investigated further,” explained Bodo Gospodnetic.

Researchers found that a ship with “defective” propeller must travel at a given percentage slower than a vessel with a “correct” propeller to operate below the cavitation inception speed and remain quiet. For example, a ship with a propeller defect of 0.5mm would have to sail at 45% of the speed of a defect-free propeller to avoid cavitation noise. The smaller the defect, the less speed reduction is required to remain quiet.