An eco-friendly or sustainable supply chain has become a critical – and ever more visible – an element of corporate social responsibility.

The trend is fueled by heightened regulations to reduce the environmental impact of industrialization. Plus, today’s consumers don’t want to be associated with an unethical company.

According to a report, 77% of consumers say they will buy a product of a company that demonstrates a commitment to environmental issues (Aflac). Similarly, secondary research conducted by hnd assignment help stats that 83% of investors are more inclined to invest in a company that acts responsibly.

Such initiatives indicate greater transparency and honesty in daily operations and financial reporting, which lowers risk.

Besides all this, investments for supply chain sustainability deliver high-pack business in the form of positive brand reputation, customer loyalty, easier access to capital, high support from the government and so on.

Five essential ways to ‘Go Green’ & achieve sustainability in the supply chain

Here are five best ways for supply chain managers to bring and maintain sustainability in their supply chain operations.

1. Mapping your overall supply chain

Lack of familiarity about the effects of sustainability on your supply chain is a major issue that may stop you from moving forward in your efforts.

A good practice is to study your own existing supply chain processes, inventory systems, and pinpoint the most significant environmental problems caused by it. Remember that the information you’ll collect during studying supply chain stage can be extremely variable from other industry players.

This map will let you know about the people, technological, natural, and other resources are being used along with your production and distribution phases.

You shouldn’t hesitate from involving your suppliers in this matter because they can offer some practical insights which can be very fruitful for getting started.

2. A cultural shift is needed

While most sustainability measures require procedural changes, some measures are only effective when a cultural change occurs. A global shift in the supply chain paradigm has been observed in recent years, but it makes no sense if your suppliers and employees are not engaged in this process.

One simple solution: Educate, educate, and educate.

Awareness, education, training, can help you align everyone with the core mission and drive behavioral changes. In simple words, tell your suppliers why it is important and how it will benefit them because it will also cultivate good vendor relationships.

You can utilize external resources or create your own material to support these efforts. Whatever you do, make sure that the workshops instill the mission from the time new employees joins the team. An effective way to create an urgency for change and transfer knowledge is to share the success stories of other companies and share the best practices of the top suppliers and companies.

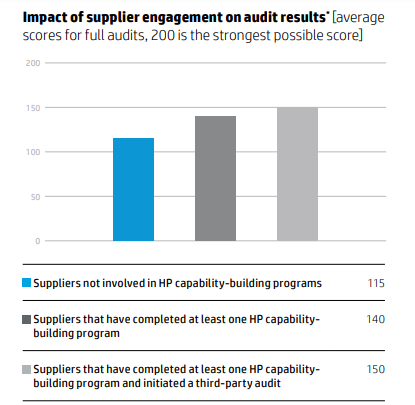

Case of Hewlett Packard (HP)

The consumer technology company HP has introduced ‘Supplier-and peer educator-run programs’ aimed at building the capacity of the larger number of workers involved. The company partnered with its suppliers and carried out more than 22 training programs in 12 countries.

As shown above, in the graph, suppliers that attended the HP-capacity building program achieved high scores in audits.

3. Ethical sourcing is the heart of SCS

Over the past decade, a number of MNCs have pledged to work only with suppliers that meet their social and environmental standards. Take some inspiration from the supplier code of conduct of the Sweden-based furniture brand IKEA.

The company heavily invested in sustainable forestry and developed a set of requirements ‘IWAY Must; for suppliers. IKEA sourced 61% (2016) and 75% (2017) of wood from sustainable sources, and this figure is constantly growing (IKEA Sustainability Report, 2023).

This issue requires a long-term strategy, but as a supply chain manager, you can do many small things to introduce sustainability in your supply chain.

For instance, choosing local suppliers over foreign suppliers will reduce transportation time, fuel cost, and carbon dioxide (CO2) emissions. There are simpler hacks as well, such as going paperless by using digital communication channels. By using tech gadgets you can share your part in saving the mother nature.

4. Leveraging supply chain technology effectively

More and more companies are adopted the latest technologies to stay ahead of the competition. The good news is that technology can also help you in making your supply chain greener and sustainable.

A lesson from Starbucks

The leading coffee chain giant Starbucks has effectively leveraged technology to transform its supply chain and make coffee as the most sustainable crop.

- The company is partnering with Microsoft to design a block chain-based supply chain tracking system to increase supply chain transparency by spotting delays and inefficiencies.

- The adoption of supply chain management technologies has reduced the paper trail associated with transportation.

- With the help of technology, the company is also making recycling cups and embracing the idea of a circular supply chain.

5. Better collaboration means better sustainability

Revolution and collaboration go hand in hand because individual efforts aren’t enough to solve complex supply chain issues. It is important for companies to pursue all their sustainability efforts in partnership with other firms.

To do this, companies should cultivate relationships with diverse stakeholders such as government, NGOs, customers, industry leaders, entrepreneurs, academic institutions, and peers.

It might feel counterintuitive to work closely with rivals, but many competing organizations share part of supply chains so collaborating on efforts means mutual benefits for everyone.

But joining resources and efforts on sustainability practices will advance objectives and offers everyone an opportunity to build a credible name in the industry and build a positive perception in the minds of consumers.

Case of collaboration

Coca Cola took an initiative to collaborate with a retail company Colruyt and a transportation company Van Dievel in an effort to make their supply chain operations efficient and sustainable.

Part of the initiative was to reduce the travel distance of trucks so that all three companies cut greenhouse gas (GHG) emissions by 30%.

Asking for collaboration or getting assistance isn’t a bad thing. The Coca-Cola and World Wildlife (WWF) project ‘Arctic Home’ is another example of collaboration for driving supply chain sustainability. The project is focused on:

- Conserving freshwater.

- Protect the arctic life and model ice conditions.

- Improve Coca-Cola’s supply chain.

- Involving WWF teams to draw their 300 best management practices for minimizing energy and water use.

Key takeaway

Over the past decades, ethical has become increasingly important in the business world. Customers are more educated, and they have many more options today than in the past. People support ethical companies and openly condemn companies that engage in unlawful or environmentally damaging practices for the sake of profits.

No firm can inject sustainability in their supply chain overnight, but the right solution and strong commitment can do the job. It’s high time for you to implement green initiatives because not only benefits companies in the short-run but also in the long-run.